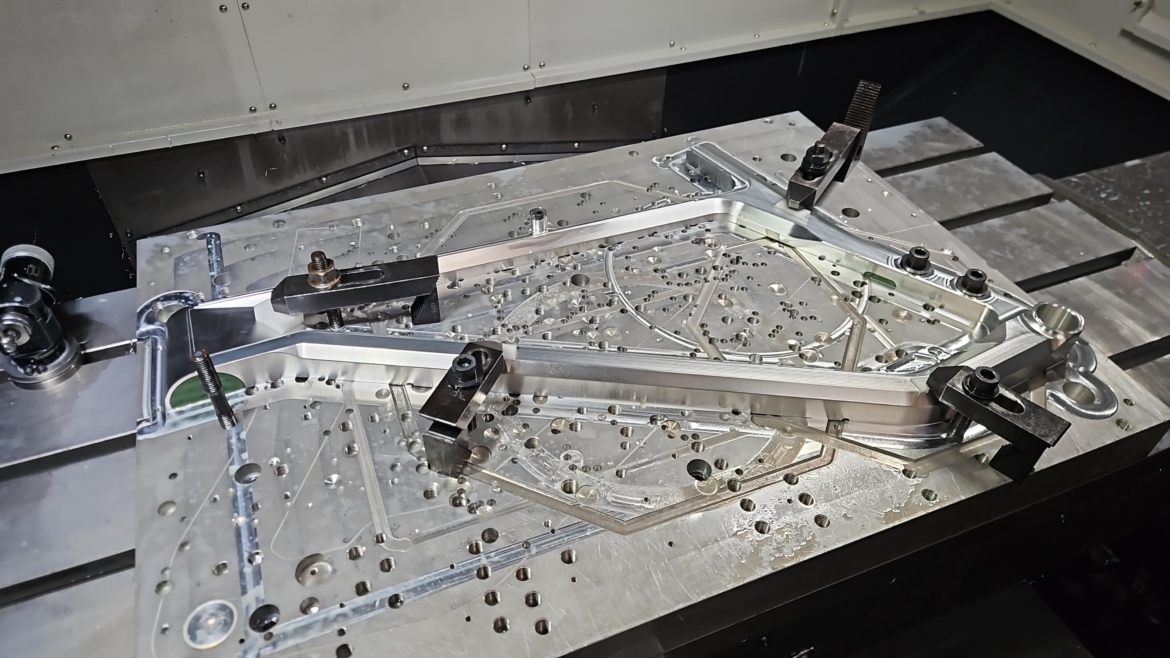

We last chatted with Chris Currie in October 2023 to hear about the launch of his new bike brand, Ministry Cycles. His Psalm 150 trail/enduro bike was a unique take on frame design: two frame halves, fully CNC’d from a single piece of aluminum and bonded together.

However, the Psalm 150 had a problem. During lab testing, Currie learned that his frame cracked around the hose ports. Knowing he needed to make some changes, Currie returned to work on his third version of the Psalm 150.

Over a year later, Currie posted good news on his growing Instagram account — the V3 Psalm 150 passed frame fatigue ISO 4210 testing. His passing score was partly due to a significant change from V2 to V3: ditching internal cable routing.

The internal vs. external debate

Between V2 and V3 of Psalm 150, Currie also received considerable help from the University of British Columbia. An engineering class wanted to take on the frame as a capstone project. In addition to helping with some redesigning, the university team was able to run some pivotal tests and simulations.

But before even sending samples to the university, Currie knew the location of the cable ports was too low on the frame. He had to relocate the cable ports for the Psalm 150 to be internally routed.

Moving the ports’ location was an option, but one that would open Pandora’s box—or, as Currie referred to it, an engineering death spiral. Moving the ports here or there would change the reinforcement in that area, which would change the reinforcement in a different location, and so on.

Ultimately, Currie realized he didn’t want cables and hoses inside the bike, deciding to eliminate cable ports altogether. The V3 Psalm 150 will have all cables and hoses routed externally, utilizing a recessed cable channel on the top of the downtube guide to secure the lines.

“There is a bit of a [external routing] movement out there,” Currie said. “The Raaw guys are doing it — there are some cool bike companies [with a] more rider-driven mentality, and they just don’t do [internal routing], and they’re unapologetic about it, as am I.”

Moving to external routing was not only the easiest way to get the frame to pass the ISO testing, but Currie also feels it is a design decision that fits his customer base. Currie anticipates reaching a demographic of bike nerds like himself: people who want to work on their bikes, enjoy trying different components, and appreciate practicality over industry trends.

To put it another way, Ministry Cycles customers are likely not first-time bike buyers.

Currie’s next steps are scary: moving toward regularly producing and selling the Psalm 150 to awaiting customers. However, there are a few more tests to run and some minor adjustments.

Regardless, Currie’s Ministry Cycles jumped a massive hurdle in passing the ISO 4210 tests.

Small batch bikes go internal

We expect external cable routing on a small-batch, CNC-machined frame like the Psalm 150. In fact, many small, handmade frame manufacturers prefer the simplicity of frames with externally routed hoses and cables.

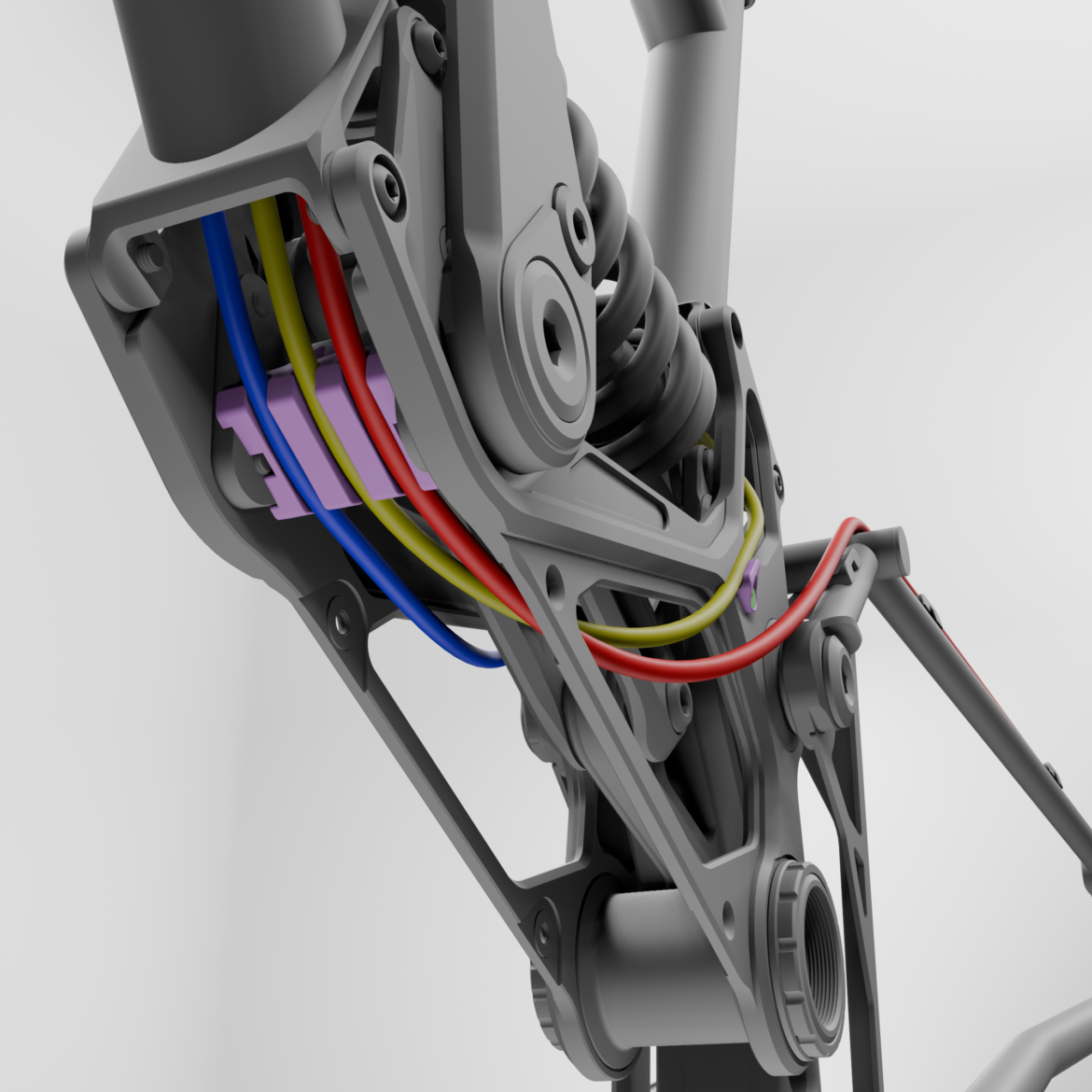

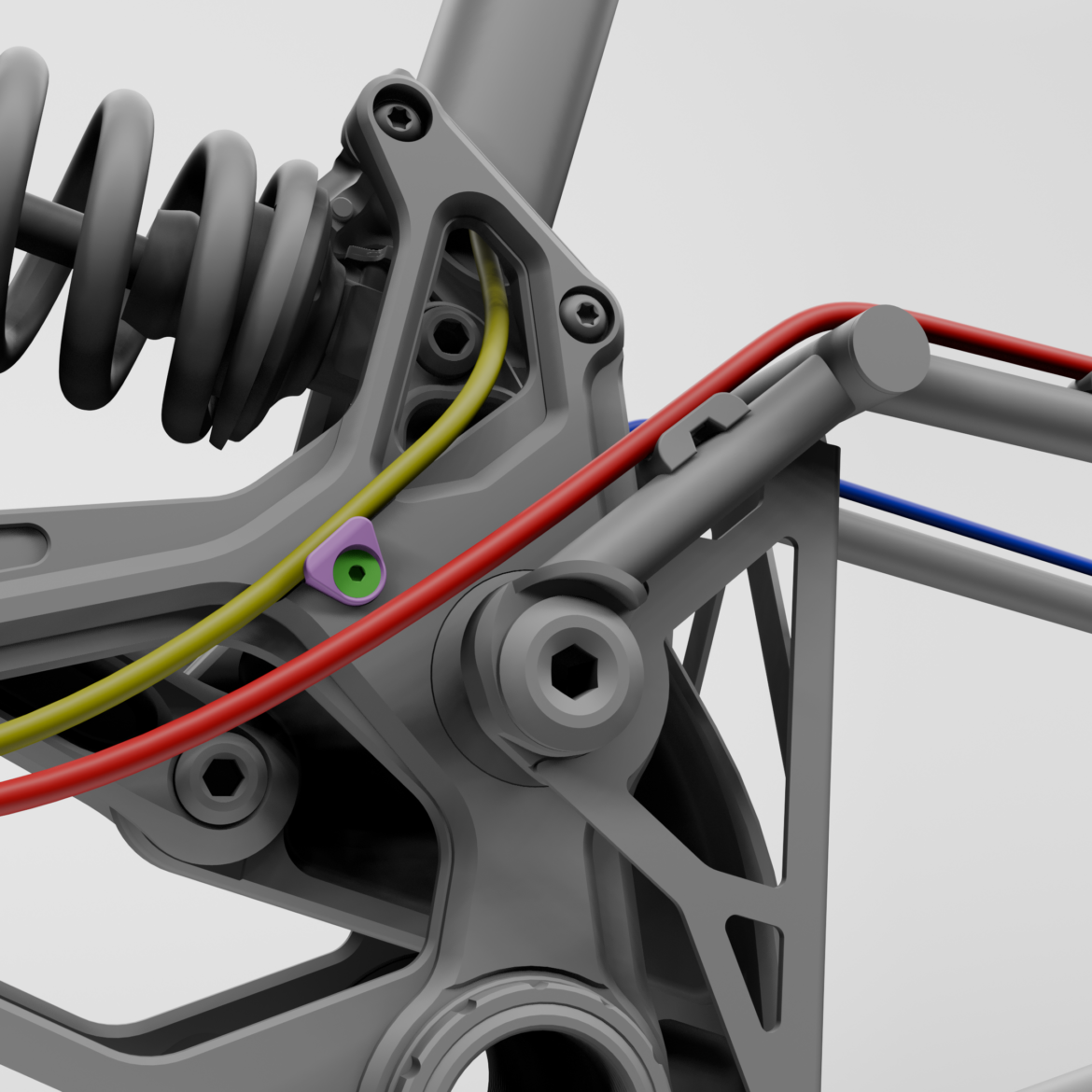

This was true when we first spoke with the guys behind the modular Apogee One nearly one year ago. Prototypes of the frame showed brake and cable lines running along the bottom of the downtube and into the suspension module. However, when we caught up with Apogee later, we found that the steel front triangles became internally routed from prototype to finished product.

Internal routing was relatively easy and just made sense for the Apogee One. The open suspension module design made routing around the bottom bracket much more straightforward than traditional bike designs.

“The way that our front triangle is designed, it terminates in an open tube that goes straight into the module,” Will Hilgenberg, Head of Product at Apogee, explained.

Switching to internal routing on the Apogee One meant adding more bracing and internal tubing for guiding, which “cost” an additional 100–150 grams. Cables enter the downtube through a port a few inches below the headtube, exit the downtube, and run along the bottom of the suspension module into the “Rocker Guide Block.” From the guide block, cables and hoses run along stays to the rear of the bike or up the seat tube to the dropper post. A removable skid plate covers the bottom of the module for protection.

Hilgenberg explained that internally routing the front triangle gave the company the desired aesthetic while making the bike easy to clean. However, if external routing is a must, Apogee can make that happen. One of the benefits of being a small-batch frame manufacturer is the ability to give the customer exactly what they want.

What about the big(ger) brands?

Pivot has been running cables and hoses inside its frames since 2007. Pivot founder and CEO Chris Cocalis explained that internal routing not only provides the cleaner look the brand desires but it is also what its customers want.

Known for their carbon fiber R&D, Cocalis explained some of the advantages of internally routing carbon frames. “With carbon, you have a lot more freedom to place the cable ports wherever you want or wherever your design dictates,” he said. “You still have to be cognizant of the frame’s structural integrity, but you are able to reinforce it more easily by modifying the mold and adding more material in the layup process.”

Cocalis went on to explain that metal frames can present more unique challenges. There are fewer design input options for the location of cable ports and a greater chance of compromising structural integrity.

The brand also uses its own Pivot Cable Port System, which Cocalis feels is superior to many competitors’ systems. Pivot’s design allows hoses and cables to be easily fed through the frame without using internal guide tubes, which add weight to the frame and can present other problems.

“Additionally, this can lead to problems over time as water, dirt, and debris get into the frame and into these guide tubes, causing the housing inside to become contaminated and possibly stuck,” Cocalis told us.

Pivot’s cable ports are covered and clamped down, preventing the issues Cocalis mentioned and eliminating rattle. The Pivot Cable Port System also allows for running brakes “moto style.”

But, Cocalis also recognizes the downsides of internal routing. Depending on the frame design, it adds extra complication to an already complicated process. It also makes swapping brakes and drivetrains difficult.

In September 2024, our Singletracks audience weighed in on the internal vs. external routing debate. Fifty percent of the survey respondents liked the clean aesthetic of internal routing, while 38 percent—perhaps more than expected—said it wasn’t worth the hassle. Comments on both the survey and social media were cordial and balanced, with many stating their preference while understanding either side.

While most riders ultimately prefer a simple, cable-free look, getting there is anything but simple, with frame strength, weight, and ease of use posing unique challenges for designers and engineers.

9 Comments

Feb 25, 2025

Feb 27, 2025

Feb 25, 2025

Mar 3, 2025

Feb 26, 2025

Internal ports caused issues during early iterations with the frames cracking around the ports.

There is less material in the headtube area...

When I spoke with a couple of them during the Taipei show they said often the frames go up a category level.

When merida launched the new one-sixty they were able to give it cat 5 and which they said it exceeded cat5 tests on both alloy and carbon models.

That's why their 140mm trail bike can live at a bike park and they will honor the lifetime warranty.

Feb 25, 2025

Feb 26, 2025

Feb 26, 2025

Feb 27, 2025