Fulcrum is a division of Campagnolo, the Italian component manufacturer with a cult-like following of highly dedicated and loyal fans. The Red Metal 29 XL (XL stands for “extra light”) is their top of the line 29er wheelset – and I have a set to test! These hoops tick all the boxes required by modern, high-end wheels: light, tubeless, convertible axle, hand built, good looks, and pricey. They also feature some interesting and unique design features, so let’s dive in.

Specs

-Hand built

-Aluminum UST Tubeless Rims

-Straight pull, over-sized aluminum spokes

-24 spokes per wheel

-2:1 lacing pattern

-Riderweight limit of240lbs

-Weights: Front, 9mm: 810g*; Front, 15mm: 800g*; Rear: 960g*; Front QR Skewer:70g; Rear QR Skewer: 80g

-MSRP: $1,000

*Note: Weight includes valve stems, but does not include quick release skewers

Straight pull aluminum spokes mated with oversized axles should make for a stiff wheel build.

Included Parts and Pieces

-Front and rear internal cam quick release skewers

-Tubeless valves (come installed on the rims)

-Spoke wrenches

-Wheel magnet for use with over-sized spokes

-15mm adapters for the front hub

-Tire levers

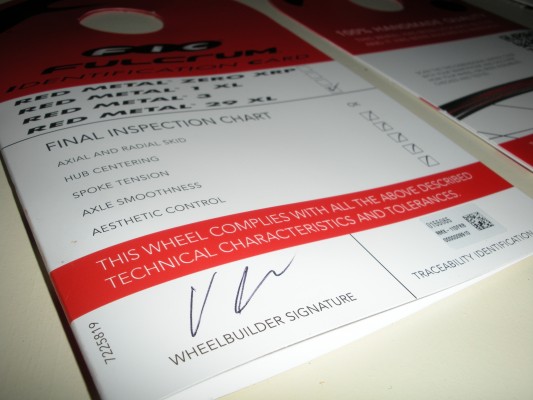

-Fulcrum identification cards signed by the wheel builder(s)

-MoMag Nippler (pretty sure that is notwhat it’s called, but it’s catchy!)

This isn’t even everything that comes with the wheels. The quick release skewers, valve stems, and computer magnet are not shown.

Hubs

The hubs are Fulcrum’s own design and are machined out of aluminum. The front wheel ships with standard 9mm quick release end caps installed, but 15mm thru-axle end caps are included.The end caps are incredibly easy to swap- no tools are needed and it only takes about 30 seconds. The rear hub is 135mm spaced and standard quick release, no thru-axle here. The freehub body is steel for improved durability, but features some very extensive machining to keep weight low. The freehub has 32 points of engagement, or, 11.25 of free play. Both hubs are 6-bolt rotor compatible,spin on over-sized 20mm aluminum axles, and featured sealed cartridge bearings.

The steel freehub body features extensive machining to reduce weight.

Spokes

Both wheels use 24over-sized, straight-pull aluminum spokes laced in Fulcrum’s trademark 2:1 lacing pattern. The 2:1 pattern puts more spokes on the higher stress side of the wheel where they are needed most, and less on the unstressed side to minimize weight. On the front wheel there are 16 spokes laced 3-cross on the brake side, and 8 spokes laced 2-cross on the non-brake side. The rear wheel uses 16 spokes laced 3-cross on the drive side, and 8 spokes laced 2-cross on the brake side. A special magnet is included with the wheels so you can still use a computer (most magnets will not work with the over-sized spokes).

Quick note: A lot of other websites have info on these wheels and say there are only 21 spokes on the front wheel, 14 on the brake side, 7 (laced radially) on the non-brake side. Even the Fulcrum catalog says there are 21 spokes on the front wheel. This is incorrect. There are24 – I counted several times to make sure, and they’re laced as I mentioned in the previous paragraph – there are no radially laced spokes, on either wheel. You can even count them yourself in one of the pictures!

I’m using the front wheel set up for a 15mm thru-axle. You’ll note that there are 24 spokes, not 21.

Rims

Quite a bit of stuff going on with these rims! They’re aluminum, UST tubeless, and come with high quality valve stems already installed. New for 2011, Fulcrum performed some extramachining on the rim between spoke holes to remove excess weight, saving 50g per rim. There are no holes inside the rim bed, so no tape or rim strips are needed for tubeless use. Since there are no holes in the rim bed, spoke nipples are installed in a non-traditional way – Fulcrum calls it MoMag for “mounting magnet.” The nipples are inserted into the rim via the valve hole, and moved in place using a magnet. The wheels even ship with the magnet and a steel insert to thread into the nipple so you can move it – I call it the MoMag Nippler.

The rims have been machined to remove excess material between the spokes to save weight.

The wheels have a rider weight limit of 240lbs, and the tech manual has a pretty good warning for anyone over 180lbs, saying the rider “must be especially vigilant and have (his) bicycle inspected more frequently.” As luck would have it, I weigh in right at 180lbs, so it’ll be interesting to see how well they hold up for me.

Each wheel ships with a Fulcrum Identification Card with a unique tracking code, and signed by the builder.

Test Time

So there you have it, now you know all about the features of the Red Metal 29 XL wheelset. I’ll be riding these wheels the next few months to see how they do out in the real world and on the trail. The wet and muddy winter, along with high water levels in creek crossings, will be a good test of the bearing durability, and my three runs at the Snake Creek Gap Time Trial will provide over 100 rocky miles of racing to test the strength of the wheels. Stay tuned!

I’d like to thank Fulcrum for providing the wheels for review.

3 Comments

Dec 3, 2011

Dec 6, 2011

Dec 2, 2011