The studious maker producing artisanal items in a shed somewhere is an oft romanticized view of cottage industry type business. Usually it’s an old guy with a beard, crafting something handed down by generations; but the truth is, that’s often not what cottage industry looks like. Archibald Cycles is a small brand dedicated to pushing the envelope, owned by a 25-year-old Canadian in Delta, BC, pumping out some of the most radical bikes on the market.

Archibald Cycles came onto my radar last year; I saw their crazy — yet beautiful — bikes on Instagram in the summer, and my curiosity was piqued. I later spotted two of the bikes at a local race series and started chatting with the owner, Alex Troughton, and promised to follow up. Fast forward almost a year, and I stopped by Archibald HQ to chat to the man behind the brand, and learn more about this business venture of his.

One of the first things that struck me about Troughton is his age. At 25 he’s been working full time on Archibald for around a year now. How many small business owners do you know that are 25 years old? Add to that the genuinely impressive workmanship and engineering that he’s put into these frames, and the vast amounts of knowledge behind it. He has a lot to be proud of, but he’s very humble.

Digging a little deeper into Troughton’s background, I learned that he worked for legendary but now defunct components brand, Blackspire, while studying for an engineering degree at UBC. He was the designer behind the Blackspire Brute pedal, while still in high school, and went on to work for a stainless steel fabrication company, before deciding to jack it in and follow his passion for bikes.

Troughton’s workshop is small; it’s essentially a single car garage on the side of his family home that’s been converted into a shop, but he gets an impressive amount done with it. No space is wasted, and just about every inch is filled with tools. This is where all the fabrication work is done: tubes are notched, frames are tacked, welded, and checked for alignment, full builds are assembled, and pretty much everything else. Because of this fully in-house production, bikes come with custom geo within a set range, with reaches from 445mm to 520mm.

Archibald currently produces one bike, the AC1, now on batch number two, and there are about 15 bikes in the wild currently. The bike itself is a high virtual-pivot gearbox bike, handmade from stainless steel. It’s tricky to see, but the AC1 linkage is basically a four bar, with a long link on the top, and the lower short link driving the shock. Troughton describes it as linearly progressive, with a small ramp up at the end, and with a very rearward axle path. He’s spent some time refining the bike over a few iterations now, landing on a version that has descending kinematics that he’s happy with, and little pedal bob.

Speaking of iterations, I asked him how he landed on stainless steel as the material of choice, and he pointed at a failed chromoly test mule on the wall. He said that it failed because the material was not produced to spec, and broke at a weld because the walls were too thin. Looking inside the broken tube, he pointed out the rust developing; he tells me that it’s almost impossible to prevent, whereas stainless is much more corrosion resistant, and is about 30% stronger. And let’s be honest, it looks great.

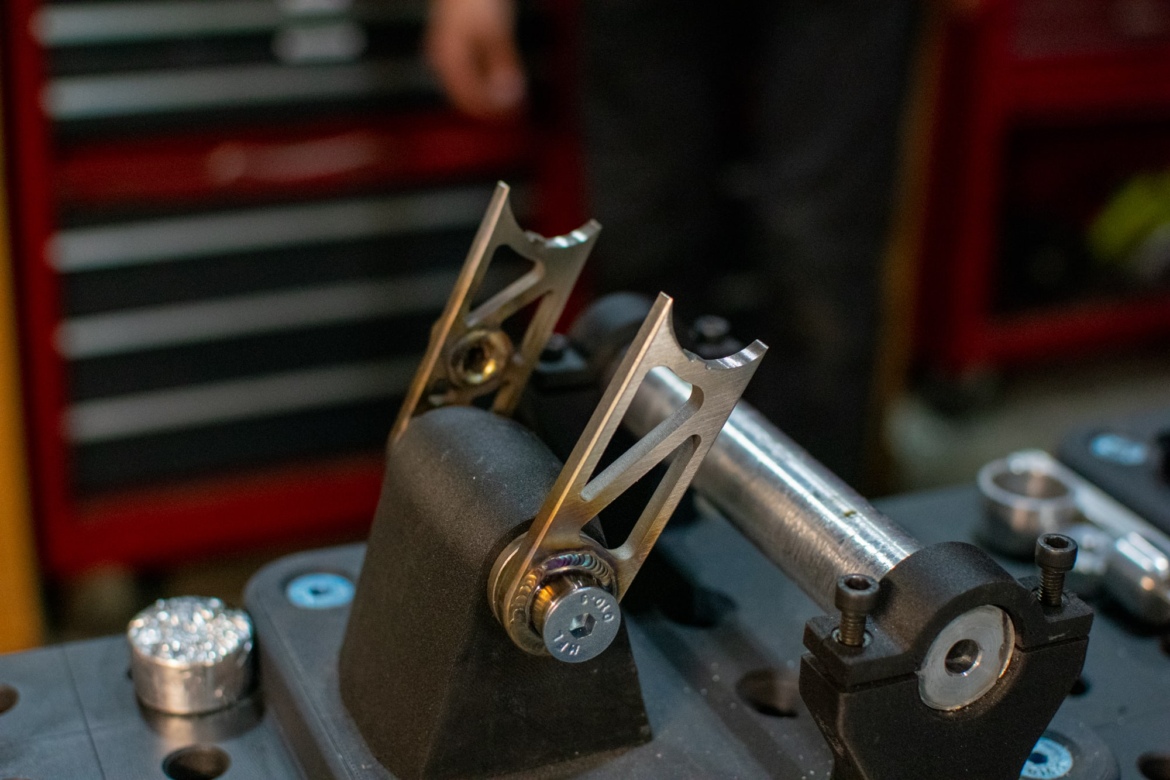

It’s clear that Troughton has thought through a lot of the details on the AC1. One area that’s particularly interesting is the shock cage, made from approximately 1mm-thick laser cut steel sheet. The part looks quite delicate, but he assures me that there’s a healthy factor of safety built into it. Most shock mounts are under compression, while his is under tension, which makes it much stronger, and less likely to fail.

The shock mounts are also modular, making it easy to change kinematics, shock size, geometry etc. The bike I rode was set up with 170mm of rear travel, but the AC1 is currently available from 157mm to 192mm, and is compatible with a fork from 160mm to 200mm.

The entire frame is made from stainless steel except some linkage/drivetrain parts; all the tubes are custom made for him, and the plates around the shock area are laser or water-jet cut locally, and welded up in house. Some aluminum parts, like the lower link and pulleys, are CNC’d by North Shore Billet in Whistler. The entire frame is designed by Troughton, and he was also doing all the welding himself too. He now has a full time welder helping him with production, and his partner helps with graphics, but that’s the whole team.

Troughton has a real passion for local manufacturing. He admires what Dustin at We Are One Composites is doing and believes he can do the same; it is still possible to manufacture in Canada, though the customer has to be willing to pay a premium price, though not out of line with other high-end bikes. An AC1 frame kit starts at $5,000CAD; add $1,750 more for an Effigear gearbox and you get the idea.

Troughton knows his customer base; he’s not trying to appeal to the masses. He tells me that he is contacted frequently by bike factories in the far east, asking him if he’d like them to produce his frames. “I just wanna make bikes,” he says. Sure, manufacture out east would cost less, but that’s not the point; his product is already niche. For somebody who wants an Archibald, shaving some percentage points off the frame cost is not a factor.

In terms of future plans, Troughton is pretty busy preparing the next batch of frames, but he’s always making changes and refinements. He says he’d also like to produce a shorter travel, more playful version, since the AC1 is a bit of a big-travel bruiser. He also has plans for a gravel/bikepacking type frame, likely something along the lines of the Hudski Dualist.

Archibald Cycles AC1 test ride

Having spent some time checking out Troughton’s workshop, it was time to hit the trails. Raised in Delta, his local trail system is Delta Watershed, a small hill with about 100m elevation, mostly covered in flow trails, with some decent sized jumps, and the odd freeride feature. The North Shore is only a 40 minute drive away, however, so Troughton is no slouch on a bike.

Asking Troughton what his primary considerations were when building his frame, it’s clear that we shared some similar ideas. He wanted to eliminate the rear derailleur as a failure point, so a gearbox made sense to him. He also wanted to produce a frame that would handle rough and gnarly trails, favoring descending speed over all else, admitting that the AC1 is not exactly a poppy or playful bike, because that’s not what he set out to make. He decided on a high-pivot layout and the rest of the design sort of informed itself.

On the trails, the bike quickly made sense to me—get it up to speed, let it rip, and it’s happy. I rode a coil shock bike with a Rockshox Zeb fork up front, and the main sensation I noticed was how smooth the bike is on rough, rooty sections of trail. The rearward axle path really helps soak up those impacts, with the bike remaining composed and stable without being overly stiff, resulting in less feedback through my feet compared to a ‘normal’ bike. This means the AC1 is a real point and shoot type of bike: it picks up and maintains speed incredibly well, without feeling uncomfortable. I could also feel the ramp up in the rear suspension. Despite landing flat on the unfamiliar trails a few times, I never felt a harsh bottom out from that coil shock. That said, it wasn’t hard to push the AC1 around corners—it felt easy enough to weight the front end and get it to go where I wanted it, likely due to the lengthening chainstays which help to transfer the rider’s weight forward.

Climbing is another matter. The seated position is good, and true to Troughton’s word, there was little pedal-induced movement, however it’s still a big, heavy bike. This was my first time riding a gearbox bike, and I could for sure feel a little extra drag in the system compared to a conventional derailleur system. There are definitely pros and cons to the gearbox, and it’s been interesting testing this and the Lal Bikes Supre Drive. Both bikes set out to achieve similar things, but approach it a totally different way. The Supre Drive is much more proprietary, but relatively low drag, whereas the AC1 feels a little more draggy, but there are a lot more options when it comes to gearboxes, and they arguably require a lot less maintenance.

Troughton tells me that one of the big pluses for him and his customers is the low maintenance on the gearbox. He wanted to build a bike that can handle a ton of abuse, with very little maintenance. Some of his customers are unlikely to even reach the 15,000km oil change interval on their gearboxes. The straight chain line means chains last a long time on these bikes, and there’s little else to maintain drivetrain-wise.

The AC1 suits Troughton’s local sponsored riders, Squamish-based Ollie Lowthorpe, and Pemberton-based Taiki Auger. For the enduro racing pair, climbing prowess is secondary to raw descending capability, and the AC1 suits their needs well in this regard, especially when it comes to doling out abuse. While bikes like this are unlikely to be the bike most people want to grab for all-day pedals, as enduro races get gnarlier, I could see the AC1 being a solid contender, especially for a privateer with little support and who can’t afford to have mechanical issues. The same goes for anyone who spends a lot of time riding tough terrain in places where they’d rather not be dealing with breakdowns, or even at a park bike.

It’s exciting to see the younger generations building their own take on the bike industry, especially here in Canada. Rather than sticking to the tried and true, there’s real innovation happening, and it’s incredible just how much knowledge these younger folk have. Manufacturing is alive and well in Canada, and there’s a real bicycle-building community here in BC with some true game changers amongst the mix. I’ve got to say, I’m all for it, and can’t wait to see what’s next.

2 Comments

May 24, 2024

May 24, 2024